Connect with our customer support team for detailed information on our product range, pricing, and customization options. We are here to help you find the perfect solution for your kitchen needs.

Factory Strength

The factory covers an area of 12,000 square meters

Our production capacity can reach 40,000 products per day

We have more than 20 quality inspectors to strictly control product standards

Transforming Culinary Tools with Cutting-Edge Design

Cooking is more than just a daily chore; it is an art and a means of bringing people together. At Ningbo Berrific, we understand this deeply, and that's why we strive to enhance every cooking experience with our innovative products.

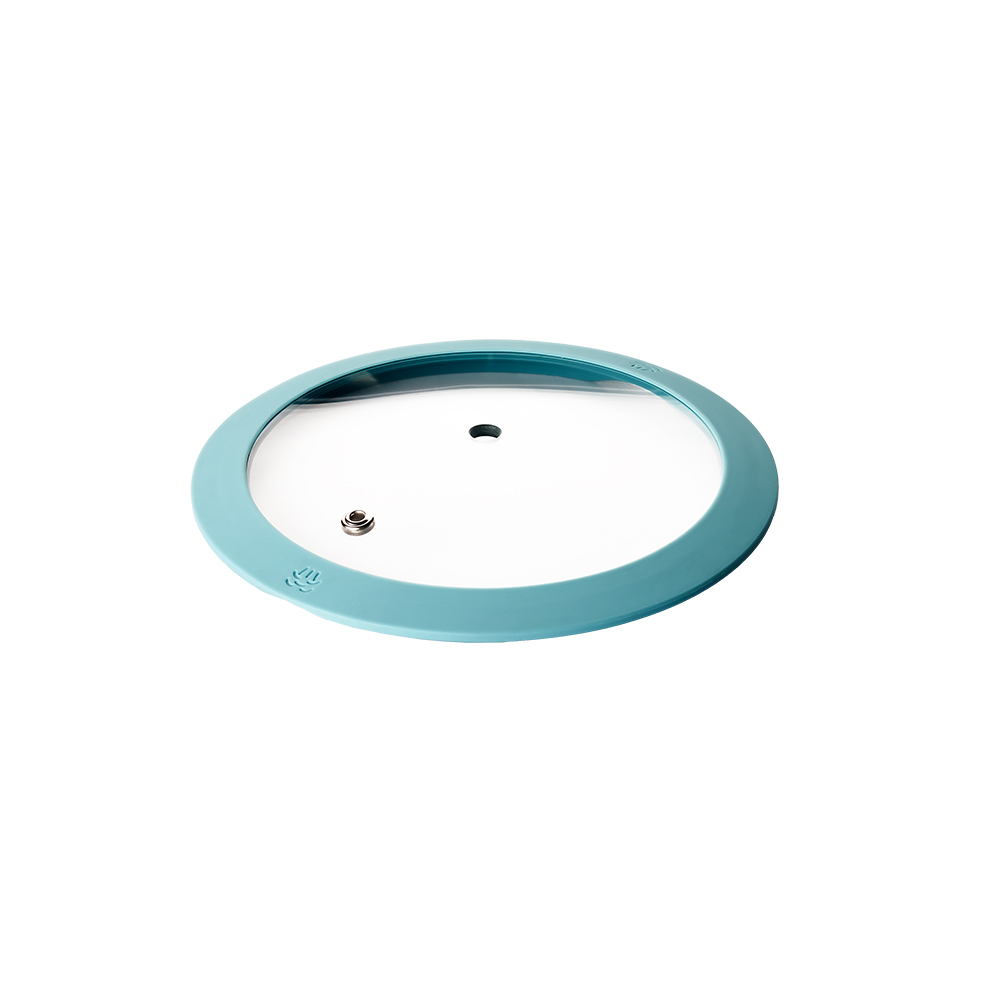

Our Silicone Glass Lids for Cookware with Side Cut Design for Detachable Handles are a testament to our dedication to innovation and quality, offering solutions that address common cooking challenges and add a touch of sophistication to your kitchen!

Key Features and Advantages

Premium-Grade Materials

Our Silicone Rim Glass Lids are constructed using the highest quality materials to ensure they meet the rigorous demands of modern kitchens. The lids feature tempered glass, renowned for its strength and resistance to thermal shock, and food-grade silicone that complies with stringent FDA and LFGB standards.

● Durability: The tempered glass we use is significantly tougher than regular glass, providing exceptional resilience against high temperatures and sudden temperature changes. This durability ensures that our lids can endure daily use in both home and professional kitchens without compromising their integrity.

● Safety: The food-grade silicone used in our Flat Silicone Glass Lids is free from harmful chemicals like BPA and phthalates, ensuring that it is safe for use in cooking. This silicone can withstand high temperatures and maintains its form and functionality without leaching harmful substances into your food.

● Ease of Maintenance: The non-porous nature of tempered glass and silicone makes cleaning straightforward. The materials do not retain odors or stains and can be easily cleaned using standard dishwashing detergents or in a dishwasher.

Unique Side Cut Design for Detachable Handles

One of the standout features of our Glass Lids with Silicone Rim is the innovative side cut design, which offers multiple benefits to enhance your cooking experience:

● Improved Usability: The side cut allows for easy attachment and detachment of handles, adding versatility to the lids. This feature is especially convenient for cookware that needs to be moved from the stove to the oven or dining table.

● Space Efficiency: Detachable handles make storage more efficient, as the lids take up less space when the handles are removed. This is particularly advantageous for kitchens with limited storage space.

● Convenience in Cleaning: The detachable handles can be removed to ensure thorough cleaning, allowing every part of the lid to be properly maintained. This feature also makes the lids more compact and easier to handle.

Expanded Range of Silicone Colours

We offer a wide array of silicone colours to complement any kitchen decor. Options include classic shades like black and ivory, as well as vibrant hues such as red, giving you the flexibility to match the lids to your cookware and kitchen aesthetic.

The Art and Science of Silicone Colour Manufacturing

Creating a diverse range of silicone colours involves a meticulous process that ensures consistency, safety, and durability. Here’s a detailed look into how we achieve the vibrant and enduring colours of our silicone glass lids.

1. Selecting High-Quality Pigments

The first step in the silicone colour manufacturing process is selecting high-quality pigments. These pigments are chosen based on their safety, heat resistance, and colour stability. We ensure that all pigments used are food-grade, non-toxic, and compliant with international safety standards.

Safety and Compliance

The pigments we use are certified to be free of harmful substances such as heavy metals and other toxins. This ensures that our silicone rims are safe for food contact and do not pose any health risks.

Heat Resistance

Given that our silicone lids are exposed to high temperatures during cooking, the pigments must be able to withstand these conditions without degrading or changing colour. Our selected pigments maintain their vibrancy even after prolonged exposure to heat.

2. Mixing and Dispersion

Once the pigments are selected, they are mixed with liquid silicone. This process involves carefully measuring and combining the pigments with the silicone base to achieve the desired colour intensity and uniformity.

Precision Mixing

The mixing process is conducted using high-precision equipment that ensures the pigments are evenly distributed throughout the silicone. This step is crucial for achieving a consistent colour without streaks or patches.

Quality Control

Samples from each batch are tested to ensure that the colour meets our specifications. This includes visual inspections as well as measurements using colorimetry equipment to verify

3. Curing Process

After the pigments are thoroughly mixed with the silicone, the mixture is subjected to a curing process. Curing involves heating the silicone to a specific temperature to set the colour and enhance the material's durability.

Controlled Heating

The silicone mixture is placed in moulds and heated in a controlled environment. This process solidifies the silicone and locks in the colour, ensuring it remains vibrant and does not fade over time.

Enhancing Durability

Curing also enhances the silicone’s resistance to wear and tear, making it more durable and able to withstand the rigors of daily use.

4. Post-Curing Quality Checks

After curing, the silicone components undergo rigorous quality checks to ensure they meet our high standards. This includes both visual inspections and mechanical testing.

Visual Inspection

Each piece is examined for colour consistency, surface defects, and overall appearance. Any components that do not meet our standards are discarded.

Mechanical Testing

The cured silicone is tested for its flexibility, tensile strength, and heat resistance. These tests ensure that the final product will perform reliably in various cooking conditions.

Enhanced Cooking Experience

Our Silicone Glass Lids for Pots are designed to bring several enhancements to your cooking routine

● High Heat Resistance: Capable of withstanding temperatures up to 250°C, our lids are suitable for a wide range of cooking methods, including baking, boiling, and frying.

● Versatility: Designed to fit a variety of cookware types, including frying pans, pots, woks, slow cookers, and saucepans. This versatility ensures that you can use our lids with multiple pieces of cookware, making them a practical addition to any kitchen.

Commitment to Safety and Sustainability

At Ningbo Berrific, we prioritize both safety and sustainability in our product designs. Our Silicone Glass Lids incorporate advanced safety features and are crafted from eco-friendly materials.

● Environmental Responsibility: Our products are made from sustainable materials to minimize environmental impact. The silicone is derived from renewable sources, and the tempered glass is recyclable, making our lids an environmentally conscious choice.

● Safety Features: The side cut design not only facilitates handle attachment and detachment but also minimizes the risk of burns and other kitchen accidents. The clear tempered glass allows you to monitor your cooking without lifting the lid, reducing the risk of steam burns.

Why Choose Ningbo Berrific

Frequently Asked Questions

Yes, our offer a wider range of customization, including specific sizes, shapes, thickness, glass colour, and steam vent requirements. Please send us your special requirements and we can incorporate it into our production process.

We will performance the following tests to ensure we provide the highest quality of the tempered glass covers:

1.Fragmentation state tests

2.Stress tests

3.Impact resistance tests

4.Flatness tests

5.Dishwasher washing tests

6.High temperature tests

7.Salt spray tests

Of course,our team is always ready and willing to visit your factory or site. These on-site visits allow us to gain firsthand insights into your operations, understand your unique needs, and provide tailored solutions. We view these visits as opportunities to strengthen our partnership and ensure that our offerings align with your evolving requirements.